Resin printing, also known as stereolithography or SLA printing, is an increasingly popular 3D printing technology. It is usually more expensive than FDM printing, so SLA printing tends to be more popular among advanced DIY users and businesses.

Resin 3D printers use liquid rather than solid plastic like filament printers use. The user fills a reservoir in the printer with liquid resin. Much like with printer filament, there are many different kinds of resins available today. Some are designed for basic printing while others have specialized features like heat resistance or medical-grade safety ratings.

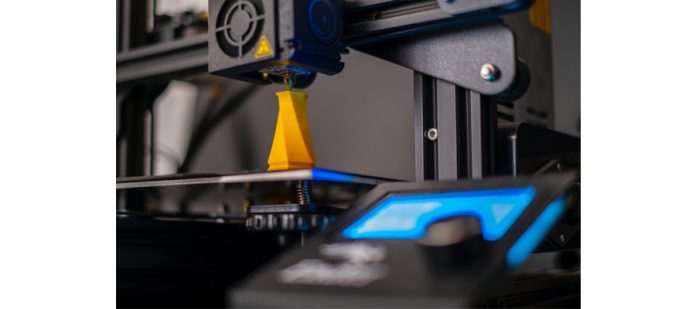

Resin printers have a different print bed design than filament printers, as well. They print models upside down, repeatedly dipping the print bed into the pool of resin and flashing it with a laser. The laser rapidly solidifies a cross-section of the liquid resin to form the model.

After the print is complete, it needs to be cured. One drawback of resin printing is that most resins are actually toxic, with the exception of medical-grade resins. So, users need to be careful about handling a resin print until it is cleaned and cured.

Users remove it from the printer using tools or while wearing gloves. A basic cleaning and curing process involves cleaning the print in two basins of isopropyl alcohol, brushing the print, then setting it aside to dry in UV light (or outside in bright sunlight). Automated cleaning and curing machines are also available today, although they can be quite expensive.

The SLA printing process is generally slower than filament printing, but it tends to deliver higher-quality prints. Resin printing is more precise than FDM, which is why it’s commonly used in medical and industrial applications. It’s great for DIY users, as well. Projects that involve small prints or fine detail are a perfect match for resin 3D printing.

Pros and Cons of Resin 3D Printing

How does resin 3D printing work in different printing applications? What types of projects are ideal for resin printing over other 3D printing technologies? There are a few key pros and cons to resin printing that highlight what it’s best for.

Benefits of Resin 3D Printing

Resin 3D printing has a few advantages over FDM printing, particularly when it comes to precision. SLA printers are generally much more accurate and precise, delivering high-quality prints with good detail and little to no layer lines. Any print that requires a high amount of detail will turn out much better with SLA printing than with FDM printing.

Due to its much higher print quality, resin printing is often the printing method of choice in medical and industrial applications. For instance, SLA printing is great for small, detailed dental implants. Resin printing is ideal for any prints like this, even everyday DIY projects like custom miniatures for a tabletop game.

Drawbacks of Resin 3D Printing

Unfortunately, there are a few important drawbacks of resin 3D printing. One of its biggest disadvantages is cost. As SLA technology has advanced over recent years, prices have started to come down. However, resin printing is still a more expensive, premium option compared to entry-level FDM printers.

This is a major reason why FDM printing is much more popular among beginners than SLA printing. Resin costs more than most filaments and one bottle of resin will typically make fewer prints than a spool of filament.

FDM printing is somewhat safer than resin printing, as well, since plastic filament is usually safe to touch. Resin prints require more post-processing, even though they have fewer layer lines to fix. Additionally, resin printers are usually much slower than FDM printers.

So, resin 3D printing is typically not ideal for large prints or making large quantities of a print. FDM printing is more time and resource efficient for these kinds of projects.

Can 3D Printing Resin Expire?

Spools of FDM filament can sit out on a desk or in a printer for days, weeks or even months at a time without any problem. This isn’t the case with resin, though. 3D printing resin can expire and typically has a shelf life of about one year. However, some resins can last up to two years.

Once a user pours resin into their printer, they need to either use it right away or carefully pour it back into a sealed container. Leaving the containers open, leaving resin in the vat or leaving resin exposed to sunlight can ruin it in a matter of hours or days. UV light and heat are also bad for unused resin.

As a general rule, users should keep unused resin in a cool place, away from sunlight, in a sealed container. This will maximize its shelf life. Before purchasing a bottle of resin, always double check that it isn’t already expired.

Is Resin 3D Printing Worth It?

How does resin 3D printing work? Are SLA printers worth the higher cost compared to FDM? It’s important to understand the pros and cons of resin 3D printing in order to choose the right printing technology. Resin 3D printing is definitely worth it for certain kinds of projects, particularly prints that require a high level of detail. It’s a great next step for 3D printing enthusiasts who want to upgrade from a more basic FDM printer.

Science writer and Associate Editor

Revolutionized