Ethernet is gaining increasing acceptance as the communication standard in industry and automation. Here transducers are a major component of modern communications technology – without them, broadband data transfer with high signal integrity would be inconceivable. Network members and cabling sections have to be galvanically isolated from each other to protect PHY chips. This functional principle is similar to a classic transformer, albeit a transformer with a focus on the best possible broadband with the good signal transmission. In order to do justice to the miniaturisation trend in industry and automation, HARTING now presents M12 PCB connectors with integrated transformer. This is a robust solution saving space and offering the best signal integrity. M12 with Magnetics – Hard shell, clever core.

Transformers are inductive components in communications technology basically built like previous ones. However, whereas classic transformers are optimised in a narrow frequency range for power transfer with the greatest efficacy, the new ones are ideal for relatively broadband data transfer with the highest degree of signal quality. Therefore, the power transfer receipt of a good signal is more important than an optimised degree of efficiency. As regards quality the signals from transformers assume a leading role in the Ethernet setting. So they ensure communication between two members of an Ethernet-based system is of good signal quality during transfer. Further important features of a transformer are linearity and minimized distortions. Indeed, distortions can lead to signal corruption, and as a result, signals can no longer be read by the recipient. In the worst scenario, this can lead to functional disturbance or downtime in an application, which is the worst situation imaginable.

Status of technology

Why then, should the signals of various Ethernet members be transferred with the highest possible quality in a complicated fashion via various inductors at all? Transformers are used for galvanic isolation, signal transmission, potential separation and symmetrisation in local Ethernet networks. Any communication based on an Ethernet protocol requires various chips and other electronic components that are very sensitive to high voltage. However, since not all devices and transmission networks in a widely ramified network possess identical potential, galvanic isolation via a transformer produces effective component protection.

Heretofore PCB cable connection has been as follows: you take an industrial connector or a suitable jack and weld it to the PCB using through-hole contacts. Chip sets and other electronic peripherals are placed next to the jack. In order to do justice to the current trend towards smallness of devices and machines, connection technology also needs to shrink. So why not also integrate chips and transformers in the connector? An outdated notion, do you think?

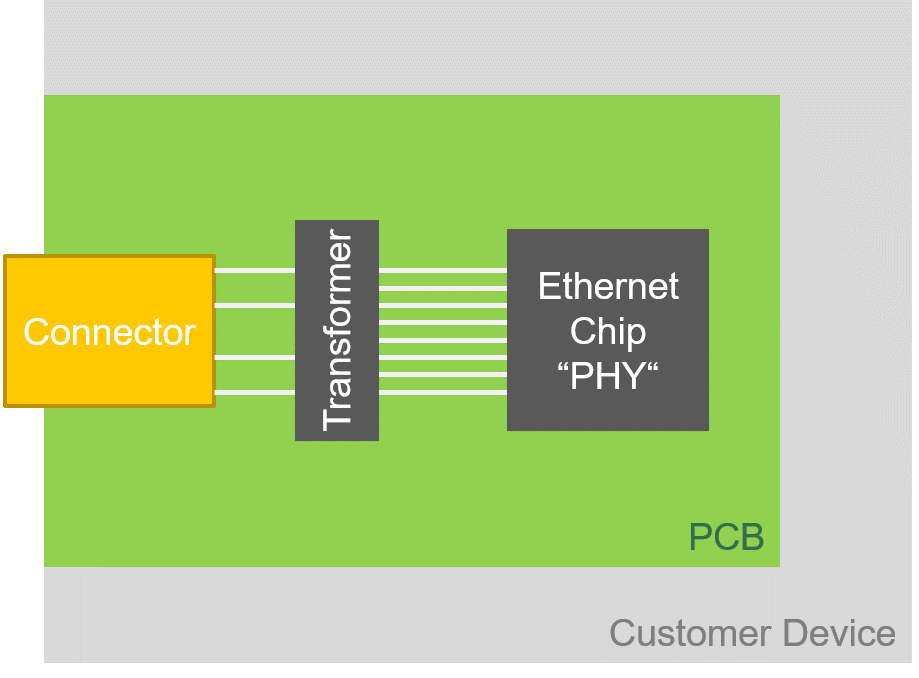

Certainly, it is. Regarding RJ45 PCB jacks, this is already standard and has become widely established in the market. But what if a robust IP65/67 protected connection is required? The following figure (1) shows the discrete structure of a solution applied nowadays for instance in the development of a switch with M12 connectors. In this process, a transformer is placed as a separate component on the PCB between the Ethernet chip and every connector and thus takes a certain space. For example, in the case of a 16-port switch, the amount of space required is huge. Here the transformer fulfills its two important functions. On the one hand, galvanic isolation and thus protection of the Ethernet chips (PHY) is ensured before current from outside is fed in. On the other hand, the effect of the transformer is to contribute to the enhanced signal quality mentioned.

Figure 1 – Previous arrangement of transformer and peripherals

Figure 1 – Previous arrangement of transformer and peripherals

Challenges in future applications

In line with the clearly-recognisable trend towards miniaturization in the industrial field increasing numbers of manufacturers are beginning to make their devices smaller, more compact and smarter. Here the most significant motivators are the desire to remain sustainably competitive and the whole subject of cost reduction.

In order to enable manufacturers to miniaturize their devices, the required components also have to shrink. Transformers used across the board render this possible in only a limited way, so for the future, a discreet structure as in figure (1) in connection with M12 connectors on a PCB takes up too much space. Traditionally used, proven components are therefore not going to be used. We need a more compact solution.

2 in 1

The solution developed by HARTING combines a classic M12 connector for the PCB and a transformer in a single component, without increasing the space required by the M12 connector. The space required on the PCB simply for a transformer is thus superfluous since this is now in the connector itself. So, as a result, a developer has the possibility of constructing his device significantly smaller and more compact. Savings of some 30% PCB space are possible per M12 connector with an integrated transformer in comparison with the structure shown in figure (2). In addition, he possesses a suitable solution as regards signal integrity, since the transformer already includes all relevant electronic components and is integrated and matched in the M12 connector. Besides fulfilling the general M12 requirements in line with IEC 61076-2-101/109 and Ethernet requirements in line with IEEE 802.3, M12 connectors with integrated transformer also meet the enhanced requirements of the railway market in terms of shock and vibration in line with IEC 61373.

In addition to a D-coded variant for fast Ethernet applications, there is to be an X-coded 1GB or 10GB version to accommodate greater transfer rates. All variants in straight and angular structure will be optional with or without PoE/PoE+ in an effort to ensure not only pure data but also energy supply to small devices such as switches.

The resulting reduction in size also for robust connection technology ensures up-to-date miniaturisation up to field level and simplifies board layout routing through surface jointing.

Figure 2 – Demonstrator with previous solution and new M12 transformer