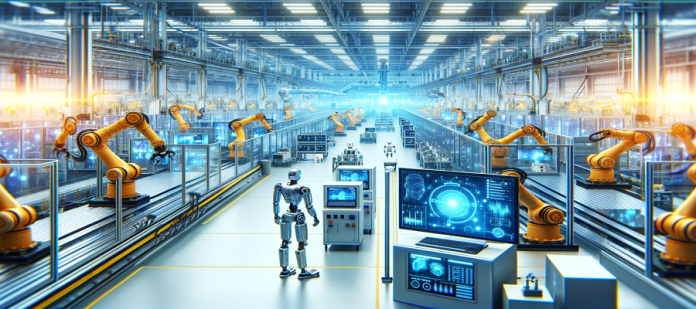

In a pioneering development, researchers at the Department of AI Machinery, part of the Korea Institute of Machinery and Materials (KIMM), have unveiled an artificial intelligence (AI) technology designed to streamline the integration of robots into manufacturing processes. Currently undergoing testing by EV parts manufacturers, this versatile AI solution is poised to revolutionize various sectors, including automobile manufacturing, machine part production, assembly, and other production processes.

The innovative technology, developed for the first time globally, promises to simplify the complex task of integrating robots into manufacturing. Researchers at KIMM have specifically tailored this AI technology for easy integration into various manufacturing processes. Currently, it is in the testing phase with electronic component producers, with plans to expand its application to a broader range of manufacturers in the future.

The AI-driven robot employs the “Large Language Model (LLM)” and operates within a virtual environment. This technology is adept at understanding user commands and automatically generating and executing tasks for the robot. It facilitates the creation of task sequences and movements through voice or text commands. By leveraging pre-learning in a virtual space, the technology selects optimal work points for the site, streamlining the work process with automatic object detection and collision avoidance capabilities.

Traditionally, the integration of robots into manufacturing sites often necessitated modifying the site to accommodate the robot, limiting the range of tasks robots could perform. The newly developed technology addresses this challenge by enabling robots to efficiently handle specific task assignments with minimal on-site modification, thanks to pre-learning in a virtual space. Ongoing on-site demonstration tests indicate that this groundbreaking AI solution is well-equipped to handle various future scenarios at manufacturing sites.