Flusso has announced a range of ‘plug and play’ gas flow sensor electronics (FSE) modules to help companies more easily and quickly integrate flow and temperature measurement features into their new product designs.

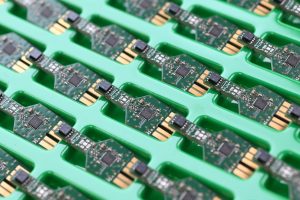

The four new modules are based on two of Flusso’s existing gas flow sensor product lines: the FLS122, launched last year as the world’s smallest air velocity sensor with a footprint of 3.5 mm x 3.5 mm, and the FLS11X series of gas flow and differential pressure (DP) sensors. Both sensor families use a unique configuration of four temperature sensing elements on a CMOS MEMS die to offer accurate real-time flow and temperature measurements.

The new modules provide a digital numerical output via I2C for easy system integration and communication within new or existing product designs.

Andrea De Luca, CEO at Flusso said:

“Flusso is introducing its new gas flow sensor electronics modules to help companies cut their development timescales and costs when adding flow measurement features into products. It means they can focus on finding the best location to integrate flow and temperature measurements within their designs, knowing that the sensor electronics have already been taken care of and are fully optimised.”

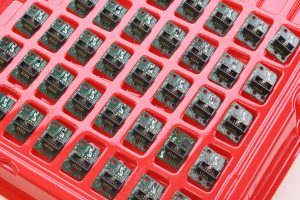

Flusso’s new modules are likely to particularly appeal to product companies bringing innovative technologies or new features to market as they can quickly develop prototype products for initial customer trials and scale up to volume production. The company’s engineering team can then easily modify its designs to replace the modules with Flusso’s lower cost sensors if required.

Target markets include new medical devices, building automation and industrial applications. The new Flusso modules can also directly replace more expensive competitive devices for manufacturers looking to cut production costs for their existing products.

The two FSE-112 modules can provide fully temperature-compensated measurement of mass flow, volumetric flow or differential pressure coupled with real-time temperature readings. One module has a PCB footprint of 22 mm x 16 mm, and the other 22 mm x 24 mm.

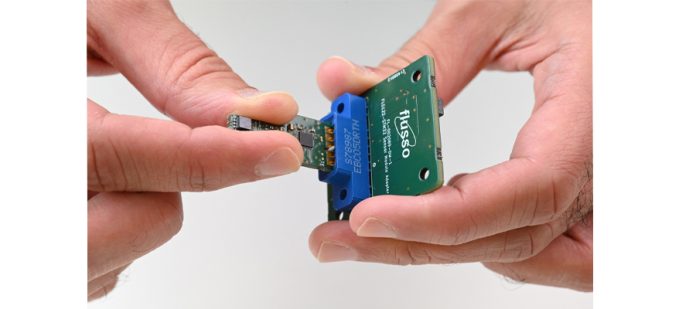

The FSE-122 module enables in situ gas velocity measurements for either smaller flow paths or larger ducts, depending on the application requirement. The module is available in two formats: a reduced size module for smaller flow paths, or a two-part extended module with an adapter board that is ideal for larger ducts.

The company is providing the same package of support materials for its FSE modules as it does for its existing sensor products including evaluation kits, hardware design guides, sensor firmware and a software development kit. It can also provide support for customers looking to include flow calibration processes on their production lines.

Flusso’s new flow sensor modules will be shown to the wider market for the first time at this year’s Sensor + Test event (9 to 11 May, Nuremberg, Germany) where the company will be in hall 1 booth 466. Sample modules for evaluation are available now and can be ordered via Flusso’s website.

1 – Flusso is launching its new ‘plug and play’ flow sensor electronics modules, shown here, to help companies cut development timescale and costs when adding flow measurement features into their products.

2 – One of Flusso’s new flow sensor electronics modules has an FLS122 gas velocity sensor positioned at the end of an extended PCB as shown above. It allows the sensor to be positioned directly in the centre of a flow path.