An electric motor is one of the three components of the eAxle of an electric vehicle.

It performs one of the most important function in an electric vehicle. It converts the energy derived from the electric vehicle’s battery into rotational force, that is, torque. This torque is responsible for propelling an electric vehicle. Both forward or backward and in the desired direction.

As a result, an electric motor has replaced the internal combustion engine in vehicles.

Hence, an electric motor is an integral and an inevitable part of an electric vehicle. Therefore, the development of electric motor is essential and imperative for any future development of electric vehicles.

Difference between a mechanical motor and an electric motor

A mechanical motor is used in a mechanical vehicle. It derives its energy from conventional fuel. It uses an internal combustion engine. This engine produces mechanical energy from the conventional fuel. This generated mechanical energy is then converted into torque by a mechanical motor.

On the other hand, an electric motor is used in an electric vehicle. It derives its energy from an electrical battery. This electric energy is then converted into torque by an electric motor.

Working principle of an electric motor

An electric motor performs its function through the interaction of magnetic fields.

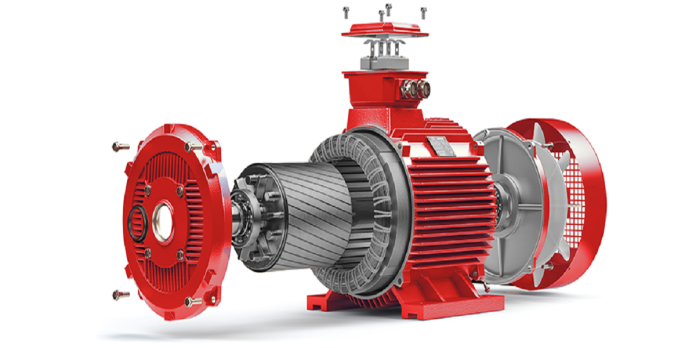

An electric motor has a stator and a rotor. The former is a stationary outer shell. Whereas, the latter is a rotating inner shell.

The stator is made up of a series of coils. These coils generate a magnetic field.

On the other hand, the rotor is made of a magnet or a series of magnets.

Now, when an electric current from the battery flows to the stator, its coils generate a magnetic field. When this magnetic field interacts with the rotor’s magnetic field, it leads to rotation. This generates torque.

Why development of electric motor and electric vehicles is necessary in today’s world?

In today’s world, there is an excessive stress on the utilisation of clean sources of energy. It is so to decrease the emission of pollutants and green-house gases. And, hence, achieve the legally-binding target of reduction in the emission of green-house gases.

Hence, it is imperative that the electric vehicles will replace the mechanical vehicles. However, in order to do so, it is necessary to make the electric vehicles operable across all terrains, all weather, and over all range of distances. Only this would increase the geographical expanse of the use of electric vehicles.

In order to overcome these challenges, the development of electric motor is of pivotal importance. Today’s electric motor have to have high torque, compact and miniaturised design, low losses, and generate high power and that too more efficiently.

Latest advancements in the development of electric motors

The major advancements in the development of electric motors are as enumerated below-

First, the powertrain of today’s electric vehicle, integrates inverter, electric motor, and charging system into a single compact unit. This results in many desirable decreases over many parameters. One, size. Two, weight. Three, generation of noise and vibrations.

Second, re-designing and reformation of the electromagnetic field circuit of the electric motor has significantly reduced the generation of noise and vibration of the electric vehicle. This has made the electric vehicles more stable in operation. Hence, more user-friendly.

Third, new permanent magnet has been incorporated within an electric motor. This has resulted in many desirable changes.

One, improvement in the efficiency of torque generation.

Two, decrease in size.

Three, reduction in weight.

Four, and most important from the perspective of strategic implications, remarkable reduction in dependence on heavy rare earth metals, such as dysprosium, in the production of electric motor. This reduction is expected to be more than 40% or more. This reduction is a remarkable achievement and has huge strategic implications. It has ended excessive dependence on few countries that possess reserves of heavy rare earth metals. It has made indigenous production of electric motor possible for every country of the world.

Fourth, remarkable progress has been made in the domain of cooling of electric motors.

Fifth, in order to make electric vehicles operable across all terrains, electric motors are being made capable of operating over a wide range of conditions- frequent starting, stopping, climbing, accelerating, decelerating, etc.

Sixth, axial flux motors are being developed to replace radial flux motors. In the case of former, the magnetic flux is parallel to the axis of rotation. Whereas, in the case of latter, it is perpendicular to the axis of rotation. The advantage of using an axial flux motor is that it provides significantly more power while having a lower weight density as compared to a radial flux motor.

Seventh, SynRM-IPM (PMaSynRM) motor. This motor is a combination of an internal permanent magnet motor and a synchronous reluctance motor. It achieves more desirable and efficient performance both at low and high speed.

Eight, in-wheel motors. These motors are also called hub motors. The remarkable feature of this motor is that it can be retrofitted to any existing vehicle platform with no vehicle modifications. It enhances the functioning of any electric vehicle. It is so efficient that it enables a car to spin on the spot.

Ninth, switched reluctance motors (SRMs). These motors are being developed for highly reliable and zero-fault tolerance applications. Developments in the fields of power electronics and the Internet of Things have given a big fillip to this category of electric motors. The special feature of these motors is that it does not use any rare earth metals.

Tenth, HET, a magnetic torque tunnel technology developed by Linear Labs, provides a three times higher torque-to-weight ratio than conventional motors. This technology has many benefits. Few of them are as follows:

One, reduces copper usage by 30%.

Two, uses readily available ferrite magnets instead of magnets made of rare earth materials.

Third, it eliminates the need for a gearbox as it itself generates a very high torque.