Introduction: The Paradigm Shift in Flexible Electronics

The emergence of flexible electronics is revolutionizing traditional rigid circuitry by enabling stretchable, ultra-thin, and lightweight electronic devices. These advances are transforming key sectors such as wearable technology, biomedical instrumentation, IoT, and next-gen display systems. Rapid breakthroughs in nanomaterials, conductive polymers, and advanced fabrication techniques are accelerating the adoption of flexible electronics across multiple industries.

Advanced Materials Engineering for High-Performance Flexible Electronics

Next-Gen Conductive Polymers and Hybrid Nanocomposites

Traditional silicon-based electronics are constrained by rigidity, necessitating the transition to flexible alternatives. Conductive polymers, such as poly(3,4-ethylenedioxythiophene) (PEDOT) and polyaniline (PANI), offer a balance between mechanical pliability and high electrical conductivity. Hybrid nanocomposites incorporating silver nanowires (AgNWs), graphene, and transition metal dichalcogenides (TMDs) enhance charge transport and mechanical durability.

Quantum Dot-Enhanced Flexible Materials

Quantum dots (QDs) and perovskite nanocrystals are being explored for their tunable optical and electronic properties, significantly improving the performance of flexible photodetectors, OLED displays, and sensor arrays. Their integration into stretchable substrates facilitates the development of high-resolution rollable screens and energy-efficient lighting solutions.

Liquid Metal Interconnects for Stretchable Electronics

Gallium-based liquid metals provide dynamic electrical pathways with self-healing properties, ensuring resilience under mechanical stress. These interconnects are pivotal in deformable circuits, allowing uninterrupted performance even under extreme bending or stretching conditions.

Cutting-Edge Fabrication Techniques for Flexible Circuits

Ultra-Precision Roll-to-Roll (R2R) Manufacturing

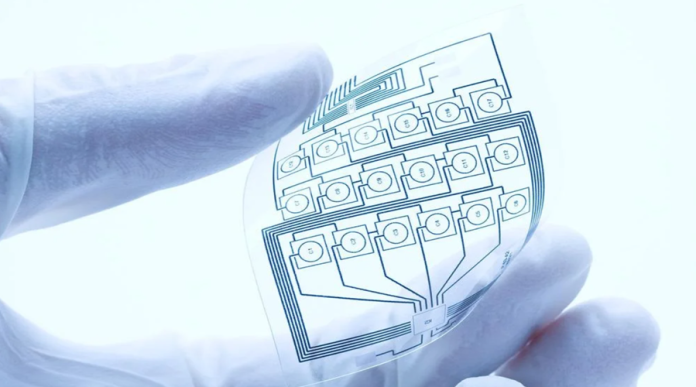

Roll-to-roll (R2R) processing is a breakthrough in large-scale flexible electronics production, enabling continuous fabrication of stretchable circuits with micron-level precision. This method significantly reduces production costs while maintaining high-throughput scalability for applications such as flexible RFID tags and sensor arrays.

Multi-Material 3D Printing for Integrated Electronics

Recent advancements in 3D printing have enabled additive manufacturing of complex electronic architectures using conductive, insulating, and dielectric inks. Multi-material 3D printing facilitates the direct integration of flexible electronics into biomedical implants, conformal antennas, and wearable devices.

Disruptive Applications of Flexible Electronics in Next-Gen Technologies

Biocompatible Electronic Skins and Neural Interfaces

Ultra-thin electronic skins (e-skins) with embedded sensors enable seamless real-time health monitoring. These biocompatible devices are crucial for applications such as non-invasive glucose monitoring, prosthetic feedback systems, and brain-machine interfaces (BMIs) for neuroprosthetic applications.

Foldable AMOLED Displays and Holographic Projections

Leading display manufacturers are leveraging flexible organic light-emitting diodes (AMOLEDs) to create ultra-thin, foldable, and rollable screens. Future innovations include holographic projection-based flexible displays that enhance augmented reality (AR) and virtual reality (VR) experiences.

Self-Powered IoT Sensors and Sustainable Electronics

Flexible electronics integrated with energy-harvesting solutions such as triboelectric nanogenerators (TENGs) and biofuel cells are driving self-powered IoT deployments. These technologies significantly enhance smart packaging, environmental sensing, and remote monitoring systems with minimal energy consumption.

Overcoming Challenges in Flexible Electronics Development

Despite remarkable progress, several technical barriers persist:

- Material Optimization: Enhancing the mechanical resilience of stretchable conductors without compromising electronic properties remains a critical challenge.

- Hybrid Integration with Rigid Components: Seamless interfacing between flexible circuits and conventional silicon-based microelectronics demands innovative interconnection techniques.

- Reliability Under Dynamic Deformation: Ensuring long-term stability under cyclic bending, twisting, and stretching is essential for real-world applications.

- Power Management: Next-gen energy storage solutions such as ultrathin supercapacitors and flexible lithium-ion batteries are being explored to meet the power demands of flexible electronic systems.

The Road Ahead: Future Prospects and Industry Adoption

Flexible electronics is poised to redefine the landscape of consumer electronics, healthcare, and IoT ecosystems. As materials and fabrication techniques continue to evolve, the widespread commercialization of these technologies will drive innovation in wearable computing, adaptive displays, and biocompatible devices. The next decade will witness a convergence of AI, quantum electronics, and flexible circuits, paving the way for unprecedented advancements in intelligent, sustainable, and seamlessly integrated electronic systems.