It may be less well known that we also manufacture full-custom, semi-custom and modified-standard products. Our engineering teams in China, Taiwan, Austria and Italy have extensive experience in product development and can design new products from the ‘ground up’ to increase the volume of production. Alternatively, semi-custom designs and modifications to existing products are offered with very competitive pricing. Modification costs are kept low because RECOM’s automated production lines offer benefits due to its economies of scale through various methods such as by reusing existing tooling and production equipment with access to our extensive on-site component stock.

RECOM also has an extensive library of platform designs to call on, particularly through our Italian sister company PCS, which specializes in fast-turnaround, high-power and full-custom solutions. These proven platform designs can often be readily adapted for other applications without necessarily incurring extensive development or certification costs.

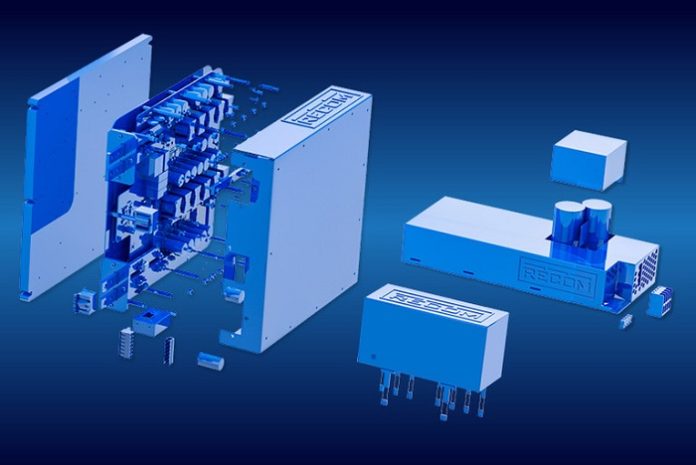

RECOM’s customization and standard product modification service include low- to high-power AC/DCs and DC/DCs, battery chargers and conditioners, AC inverters, PFC front-ends and much, much more. All major application areas are covered – including industrial, medical, energy, aerospace, mobility and military COTS. According to customer requirements, fully customized and semi-custom products can also be supplied with the necessary safety and EMC certifications.

Martin Rausch, the CTO of RECOM comments, “For many years, we have offered customer-specific modifications to our standard products, so we may already have a version that matches your special requirements. If a full-or semi-custom design is a solution, RECOM can be your design partner for any application and market.”