When asked how they envision a robot, most people either think of huge, unwieldy robots working in fenced off areas in large factories. Or, they think of futuristic cyber-bots mimicking human behavior.

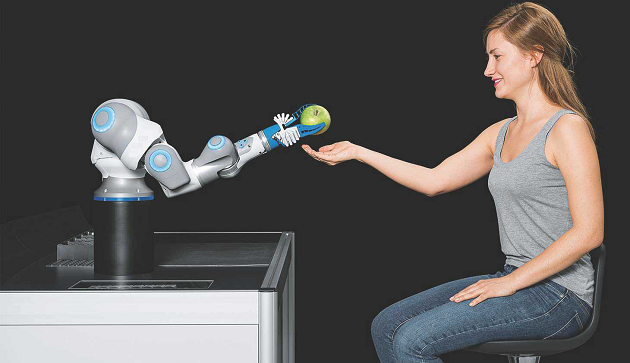

But somewhere in between these two scenarios lies a new emerging reality: A new class of robots, dubbed collaborative robots or – simply cobots – poised to bridge the gap between fully-manual assembly and fully-automated manufacturing lines.

Unlike their big brothers working inside safety fencing at automobile plants and other large assembly lines, collaborative robots are lightweight, flexible and can easily be moved and reprogrammed to solve new tasks, meeting the short-run production challenge faced by companies adjusting to ever more advanced processing in smaller batch sizes. Innovative force-sensing technology enables the UR-robot to automatically stop operating if it encounters obstacles in its path which means the robot can work right alongside employees with no safety guarding after performed risk assessment.

Lowering the entry barrier

According to the old rule of thumb, the cost of a robot would be equivalent to one worker’s two-year salary. But collaborative robots are closer to one fourth of that price.

With traditional robots, the capital costs for the robots themselves account for around a quarter of the total system costs. The remaining costs are associated with robot programming, setup, and dedicated, shielded work cells. The “out of box experience” with a collaborative robot is typically less than an hour. That’s the time it takes to unpack the robot, mount it, and program the first simple task through an intuitive touchscreen user interface. Or, by simply grabbing the robot arm, showing it the desired path of movement.

Safety first

Safety has been a hot-button issue and the major thrust of research and development in robotics labs for a long time. With human collaboration in mind, the new generation of industrial robots consists of rounded joints, back drivable motors, force sensors, and lighter weight materials. Features that can help solve many automation headaches in work cells unable to accommodate safety guarding or where the application requires regular human-robot interaction.

New guidelines on risk assessment

When designing for safe human-robot collaboration, there are two things to consider: the robot itself, and the application. Universal Robots offers a collaborative robot which is certified by third parties to meet the current cobot safety standards. The second thing to consider is the application itself, and the safety hazards that may present. A robot is never inherently safe; the risk assessment of the entire application should always be conducted. For example, the robot may be picking up a part with sharp edges, and moving it quickly at head-height. In that case, the integrator should consider what is safe if the tool or product were to hit a person.

With the introduction of ISO/TS 15066, integrators now have a guideline for acceptable force for different parts of the body, so they can cater the safety settings to be appropriate for the specific application. Universal Robots offers configurable safety settings where the user can define the limits for force, power, speed and momentum so the robot can work safely, on an application defined basis.

Speed vs. safety

In building the robotic work cell, a couple of key questions should be addressed: What is the required cycle time of the machine to get sufficient ROI? Speed and safety can often compete in an application, but it’s important to consider the benefits of removing guarding and allowing for greater operator involvement. As a machine becomes closer to 100% automated, the overall cost tends to rise exponentially. Certain tasks can be very challenging to automate, which adds significant cost. Those types of tasks include anything subjective such as bin sorting, or complex inspection tasks. By slowing down the process so that you can consider a collaborative robot, you allow human operators to be involved in the more challenging portions of the task, reducing automation cost.

Plug and play integration

Another cost efficient element is quick integration. While the UR robots themselves are easy to use, outfitting the robot arm with the required end-effectors and accessories required to handle automation tasks, however, can be a trial-and-error process. Universal Robots has changed the way that we approach integrating third-party hardware with a robot, with the introduction of Universal Robots+, a showroom of Plug and Play application solutions offering a new level of simplicity for companies that want to hit the ground running when installing their next UR robot application; By choosing accessories, grippers, and software solutions from Universal Robots+, both distributors and end-users get high security and predictability that their entire robot application will run well from the start, saving weeks and months in the integration process from concept to operation.

Bridging the skills gap

A reason for speeding up the entry of cobots is not only to optimize production here and now. Bajaj Auto Ltd. saw a gradual rise in the productivity and efficiency in their production. It also increased the productivity of their employees along with their product quality after associating themselves with Universal Robots. They have deployed over 150 cobots since 2010 and are now the 3rd largest motorcycle manufacturer in the world. They are of the view that the added benefits of the co-bots are easy use, very low annual maintenance and higher energy efficiency.

Universal Robots have been working with Aurolab which is associated with the healthcare center. The labor force at Aurolab actually increased from 15 to 700 and production improved from 150 to 10,000 Intra Ocular Lenses (IOL) per day. They are exporting to over 130 countries due to superior quality of their lenses. Aurolab have seen a 15% increase in the annual product output. Aurolab is associated with the Arvind Eye Care Systems and have provided them with co-bots that have increased affordability helping people regain vision at lower cost, and has considerably reduced the power consumption and quality problems.

While machines can’t replace human workers in many production processes, even the smallest companies are finding collaborative robots an easy-to-deploy solution for this worker shortage.

But in order to bridge this gap, we have to raise the robot literacy. Universal Robots along with our new UR Academy are both initiatives that we have launched to address this.

Universal Robots Academy is free e-learning modules that make up the basic programming training for UR robots. This includes adding end-effectors, connecting I/Os and setting up safety zones. The modules are not merely a passive transfer of information but built to deliver hands-on learning via interactive simulations to maximize user engagement.