CNC (Computer Numerical Control) soldering is an automated process where soldering tasks are performed using a programmable CNC machine. It allows precise control over the soldering process, ideal for repetitive and intricate soldering tasks in electronic manufacturing. The CNC system guides the soldering tool along pre-defined paths to achieve accurate solder joints.

How CNC Soldering Works:

- Design Input: The process starts with CAD/CAM software to create a digital design of the soldering task.

- Programming: The design is converted into machine-readable G-code, which guides the CNC soldering machine.

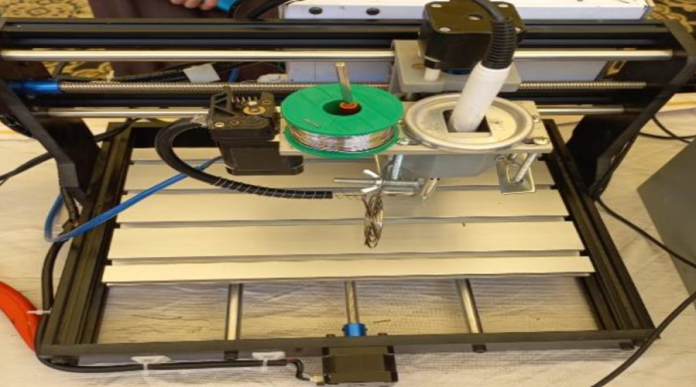

- Machine Setup: The soldering tool (e.g., soldering iron, laser, or ultrasonic tool) is mounted on the CNC arm.

- Execution: The machine follows the programmed path, precisely applying solder to designated areas, ensuring consistent quality.

- Inspection: Automated or manual inspection ensures solder joints meet required standards.

CNC Soldering Process:

- Preparation:

- Load the components and PCB (Printed Circuit Board) onto the machine.

- Input the soldering design and settings.

- Heating and Solder Application:

- The CNC tool applies heat to the solder and component leads.

- Solder flows to form a secure joint.

- Cooling:

- The joint is allowed to cool naturally or with cooling systems to solidify.

- Quality Check:

- Joints are inspected for accuracy and integrity.

CNC Soldering Uses & Applications:

- Electronics Manufacturing: Ideal for PCBs in consumer electronics, automotive electronics, and medical devices.

- Prototype Development: Rapid soldering of prototype boards with consistent quality.

- Aerospace and Defense: Precise soldering for high-reliability applications.

- LED Assembly: Used for accurate placement and soldering of LED components.

- Telecommunications: Efficient soldering of intricate circuit boards for communication devices.

CNC Soldering Advantages:

- Precision: Ensures accurate soldering with minimal errors.

- Consistency: Delivers uniform quality across all joints.

- Speed: Automates repetitive tasks, reducing production time.

- Scalability: Suitable for both small-scale and mass production.

- Safety: Minimizes manual handling, reducing risks to operators.

- Versatility: Compatible with various soldering tools and techniques, including laser and ultrasonic soldering.

CNC Soldering Disadvantages:

- High Initial Cost: Significant investment in CNC machines and setup.

- Complex Setup: Requires skilled personnel for programming and maintenance.

- Limited Flexibility: Less adaptable to on-the-fly changes compared to manual soldering.

- Material Compatibility: May not suit all types of soldering materials or components.

- Maintenance Requirements: Machines need regular calibration and upkeep.

CNC soldering is a cornerstone of modern electronics manufacturing, combining efficiency and precision while offering cost-effective solutions for high-quality soldering needs.