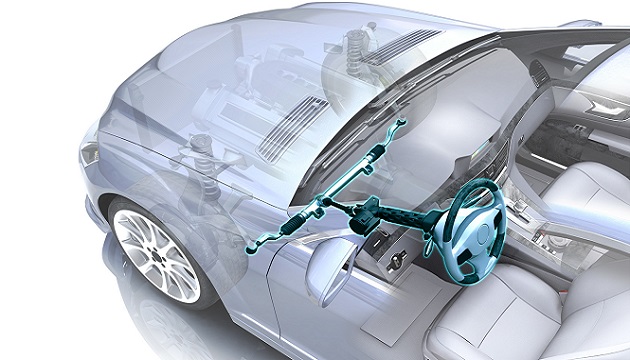

Electric power steering (EPS) has almost completely replaced hydraulic and electro-hydraulic systems. The advantages are obvious: They include higher energy efficiency, as there is no need for a constantly working, belt-driven pump. In addition, eliminating the hydraulic components simplifies manufacturing and maintenance. However, a reliable and efficient electric power steering system requires fine-tuned solutions based on powerful semiconductors. Infineon offers a chipset for upcoming EPS generations that includes all major semiconductor components such as power supply, microcontrollers, half-bridge drivers, MOSFETs, CAN transceivers and sensors. All of these components are already available. From a single supplier, customers receive everything included in a fine-tuned chipset, which will help to reduce development time and thus costs.

Why supply an entire EPS chipset? The goal was to provide all the necessary semiconductor components for an electric power steering system and fine-tune them in a way that leads to a high level of availability and enables fail-operational or fail-safe operation. Correspondingly, coordinated components offer reliable interoperability and integrated compatibility. An important aspect was to guarantee functional safety – for this, all the relevant components not only have to meet the highest automotive quality standards, but also have to be designed according to ISO26262.

EPS demonstrator

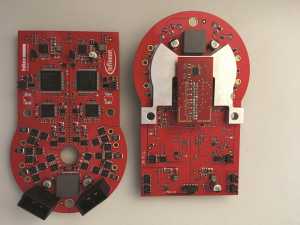

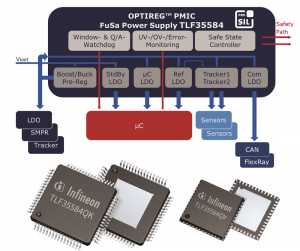

Infineon has developed a demo board with chipset components and a mechanical demonstrator. The demo board controls a 6-phase electric motor. Fig. 1 shows the demonstrator set-up and Fig. 2 the demo board with all the chipset components. They include the power supply chips (OPTIREG PMIC, TLF35584), 3-phase half-bridge drivers (TLE9183QK), 32-bit microcontrollers (TC23x with 200 MHz and 2 MB Flash), torque sensors (TLE4998C8D), motor position sensors (TLE5309D) and angle sensors (TLE5014D), MOSFETs (in the SS08 package) and the CAN FD transceivers (TLE9251VLE, TLE9252VLC).

All components used are well matched and designed for high functional safety, energy efficiency and integration density. For example, the safety power supply is predestined for EPS systems and offers corresponding monitoring and protection functions for ASIL D functionality, which is also supported by the bridge driver. All sensors are designed for systems according to ISO26262 and offer very high measuring accuracy. The powerful microcontroller from the AURIXä family can be selected for performance, flash capacity, timer architecture and peripherals. In addition, the MCU has an integrated safety/security concept with ISO26262 support, hardware redundancy and hardware security (HSM module). Finally, the MOSFETs offer very low on-resistance (RDS (ON) of 0.9 mW at 40 V) and excellent switching performance in small, rugged packages (SS08 or sTOLL).

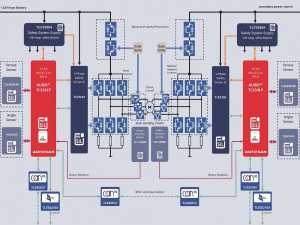

The demonstrator architecture is a 6-phase system with two independent, isolated 3-phase subsystems for the required redundancy (Fig. 3). Therefore, the dual sensors, power supply chips, microcontrollers, half-bridge drivers and MOSFET half bridges can be powered by two independent batteries for a fail-operational system. Both subsystems run independently of each other. Each of them contributes half the torque to the entire EPS system. In the case of a fault and thus a failure of one subsystem, the other would take over the EPS functionality on a proportionate basis.

Precision sensors for high functional safety

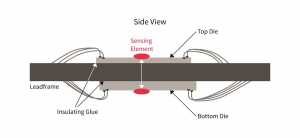

In order to ensure high functional safety in cars, a system partitioning with redundancy and efficient, reliable sensors is required. This is the only way to ensure a high level of availability, thereby enabling the system to remain fully functional in the event of a component failure. Therefore, sensors in electric power steering systems must not only be very precise, but also ensure functional safety. The sensors used here can be applied in ISO26262 systems. Infineon’s answer to the demand for sensor redundancy is integrating two sensors in a dual-sensor package (Fig. 4).

The linear Hall sensor TLE4998C8D ensures accurate detection of the torque or steering moment. It very precisely scans the linear or angular position and digitally compensates temperature and mechanical stress, which ensures excellent stability over the entire temperature range and lifetime. The TLE4998C8D integrates two independently programmable linear Hall sensor ICs with SPC (Short PWM Code) protocol. The protocol allows the measured data to be transmitted initiated by the control unit. For flexible use, customers can choose between different interfaces (SENT, SPC, PWM only as single-chip).

The TLE5014D angle sensor is also a dual-chip version. This allows easy implementation of the required redundancy in system design. The sensor works extremely precise over the entire temperature profile and lifetime, making it ideal for use in power steering applications. The sensors are preconfigured with respect to the settings and precalibrated with respect to the temperature. As a result, customers can easily implement them. Again, customers can choose between different interfaces (SENT, SPC, SPI and PWM).

The dual-sensor chip TLE5309D combines an AMR and a GMR sensor with diagnostic functions in one package. The dual GMR/AMR angle sensors are used for analogue angular position detection in safety-critical motor applications. The TLE5309D combines the very high accuracy of the AMR sensor with the wide measuring range of 360 degrees of the GMR sensor. Thanks to a short propagation delay (less than 9 ms) the sensor is prepared to meet highest requirements regarding speed and accuracy in electric motors and electric power steering systems. In addition, the sensor also offers a quick start of less than 70 ms and a low total power consumption.

Safe power supply and powerful half-bridge driver

Safety-relevant systems also require a monitored voltage supply to ensure the functionality of the system components. The power supply and monitoring device TLF35584 (Fig. 5) supports ECU designs in the context of ISO26262 up to ASIL D. The relevant main monitoring functions of the TLF35584 are undervoltage/overvoltage monitoring of the generated supply voltages, external watchdog monitoring of the microcontroller and external monitoring of the safety management unit of the AURIX MCU. Integrated monitoring of the status of these monitoring functions is made possible by a microcontroller-independent shutdown path for the system via the “safe state” outputs. Voltage monitoring is supported by a self-test (BIST).

The TLF35584 provides voltage to the controller through separate controller outputs with a monitored voltage for the microcontroller (3.3V or 5.0V, selectable), its analogue-to-digital converter (ADC), standby controller, multiple transceivers, and sensors. For sensors, two independent tracker outputs are available, which are essential for setting up the safety-relevant sensor systems. The voltage regulation is based on an architecture with a DC/DC pre-regulator and linear post-regulator. To support cold-start-relevant systems, the TLF35584 offers an optional boost converter for input voltage stabilisation and functional range expansion up to a battery voltage of 3 V.

The TLE9183QK 3-phase half-bridge driver IC has also been developed according to ISO26262. It has extensive protection and monitoring features, including limp home functionality. The power cycle can be adjusted from 0 to 100% without restrictions. Other features include three current sensor amplifiers, a low quiescent current operating mode, and a phase voltage feedback function with SPI programmable thresholds.

Safety microcontrollers

The 32-bit multicore microcontrollers from the AURIX family are tailored to the needs of powertrains as well as automotive safety applications. The family is highly scalable (single, dual or triple core, 80 to 300 MHz, 0.5 to 8 MB flash memory, etc.) and is available in numerous package options. With high real-time capability and integrated safety/security features, the AURIX family is the ideal platform for a wide range of automotive applications. This includes engine control units, gearbox controls and controls for electric and hybrid vehicles, as well as suspension systems, brake systems, electric power steering systems, airbags and driver assistance systems.

The AURIX architecture was developed following an ISO26262-compliant process. It is designed so that ASIL D security requirements can be implemented in a very efficient manner. The microcontrollers combine a powerful multicore architecture along with specialised security technologies such as secure internal communication buses and a distributed memory protection system. Special protection mechanisms allow the integration of software from different application areas, allowing multiple applications and operating systems to run smoothly on the AURIX platform, even with different ASIL ratings. In addition, a hardware security module (HSM) is integrated for high protection against manipulation.

Outlook

The complete Infineon EPS chipset will be available from mid-2019. In addition, in a subsequent step, increased performance, integration density (more functions and a reduced package size) and further improvement of the EMC robustness are planned. This means that even more powerful components with a new microcontroller (new generation of AURIX microcontrollers), power supply ICs, half-bridge drivers and sensors will be available for the upcoming EPS chipset generation.

With regard to future stages of automation (level 3 and higher), the demands on electric steering will also increase. Steering systems without the mechanical coupling between the steering wheel and the steering gear used to date are expected in the market. These steer-by-wire concepts require even higher availability and reliability. Infineon’s EPS chipset also refers to these future applications, enabling future-proof steering system designs.