Across industries, there is a call for machines that operate with low power but with precision, stability, and high-speed production. From AI-enabled robots to machines that can give us a 3D-printed heart, efficiency is certainly a driving factor. People and companies want equipment with high capabilities, without sacrificing safety or ability.

Robot Safety in Work Environments

The Robotics Industries Association recently announced a partnership with the Occupational Safety and Health Administration, a partnership that makes sense given the emergence of robots in places like manufacturing, logistics and fulfillment, and even agriculture. Robots are showing up everywhere—they’re making our food, building our parts, and surveying our land. But are they doing it safely?

ZDNet reports that statistics indicating robot workplace safety are encouraging in both professional service robots (which operate unidirectionally with humans) and collaborative robots (which perform work in the same space as humans).

Since 1984, there have been only 38 robot-related accidents, 27 of which resulted in an employee’s death. These involved only professional service robots and most occurred during maintenance. The Bureau of Labor reports that, in 2013, when the last robot-involved death occurred, 4,585 people died in the workplace overall, making robot-related deaths comparatively infrequent. To prevent further accidents, OSHA will be examining and enforcing safety standards in human and robot work environments.

In collaborative robot situations (also known as “cobots”), robots rely on proximity and force sensors, as well as 3D cameras and LiDAR to engage with humans without incident. They consist of lightweight manipulator arms and end effectors, which reduce the risk of injury. They’re highly precise, stable, and in control, which helps both safety and functionality, so their ability to operate well is paramount. Cobots can already be found in manufacturing facilities around the globe.

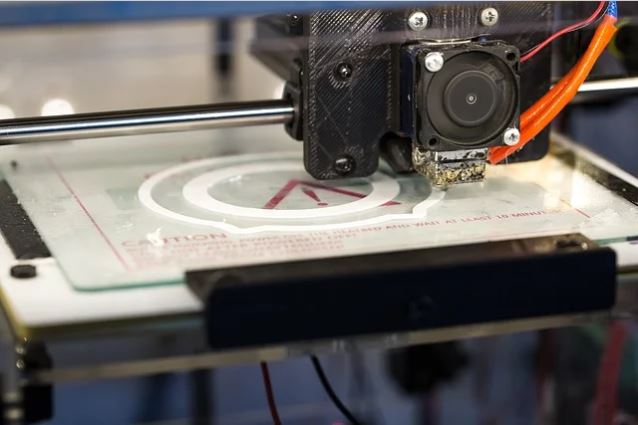

3D Printers for Medical Devices

While 3D printers long ago established their place in the tech sphere, they’re beginning to prove their usefulness in medicine. It is now possible to print medical devices that are complex, customized, and highly versatile.

3D-printed implants and devices have the potential to revolutionize the industry, especially since they allow for low-cost customization unlike their metal and ceramic counterparts. They also offer accurate renderings of 3D files and can even serve as replacement scaffolds for porous bone replacement, offering more stability over time. Of course, this requires machines that operate efficiently and with a high degree of precision.

A Possibility for Improvement

Toshiba recently announced the introduction of three new stepper motor drivers that detect the excessive load on a motor and automatically adjust power to the motor to accommodate this load. The TB67S249FTG, TB67S279FTG, and TB67S289FTG allow motors to move very quickly and with precision under various load amounts. Toshiba claims that they minimize power consumption, heat generation, and overall system costs.

Under circumstances in which motors are asked to operate with loads heavier than they were designed for, motion decreases and the motor may even stall. Stepper motor driver solutions seek to avoid this by driving excess current to allow an operating margin for less than ideal conditions. Unfortunately, this results in inefficiency, high heat, issues with reliability, and higher costs. Other solutions add sensors and microcontrollers which increases costs, PCB space, and complexity of the design.

Toshiba’s stepper motor drivers claim to be the first to incorporate proprietary anti-stall and active gain control technology, which monitors motor torque and optimizes motor current based on load requirements without another microcontroller.

“Applications such as robotics, precision manufacturing, and 3D printing require stable, precise, and high-speed control. The low power, anti-stall, and AGC capabilities of these new Toshiba stepper motor controller products lower system costs, improve efficiency, and improve system reliability for these applications,” says Alan Li, senior business development manager for motor control products at Toshiba.

The TB67S249FTG supports a max operating voltage of 50 volts and drives 4.5 amps to max current, while the TB67S289FTG and TB67S279FTG drive 3.0 and 2.0 amps.