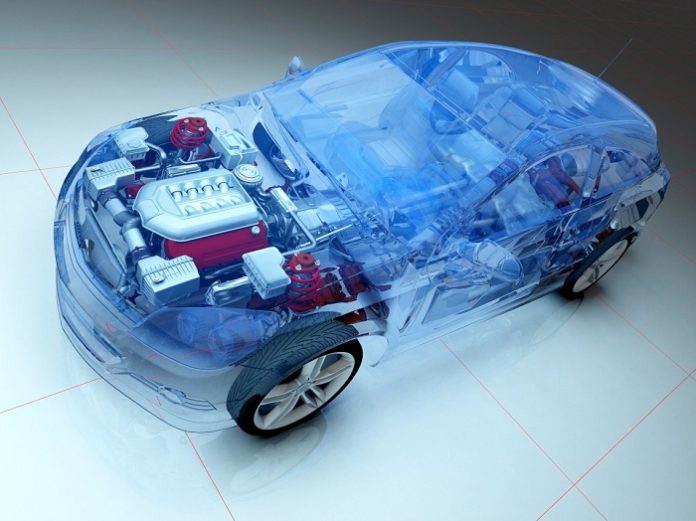

The whole automotive industry is undergoing a big shift towards electrification. There is no doubt that each manufacturer is targeting to develop or redesign their next-generation electrical system. The electrical system within an EV car covers a wide aspect of functionality responsible from high to low voltage systems. Typically for high voltage systems, we are referring to the Electrical Control Unit (ECU) responsible for OBC, DC-DC, traction motors, HVAC inverters and BMS systems. Within these few ECU examples, the requirements for electronics, in particular, MCU and high voltage switches (MOSFETs) are getting more and more demanding in terms of processing power, security, power efficiency and connectivity. In terms of a centralized low voltage electrical system, we usually refer to these as the centralized computing module to support vehicle controls responsible for body application, autonomous driving and human-machine interfaces. It is accurate to say that we are seeing trends to use central computing as one big brain within a vehicle, but this is only part of the story. OEMs have the vision to split vehicle control from the existing domain control into zonal-based architecture using central computing as the main backbone and utilizing high-speed ethernet communication as the main connectivity. This type of architecture certainly brings multiple opportunities for Microchip due to even higher demand for MCUs within the whole zonal architecture which ensures scalability, flexibility and reduced complexity for OEMs.

Microchip has been supplying automotive semiconductor solutions for over 20 years. With the shift of the automotive market towards electrification and autonomy, we are seeing tremendous growth potential as a key enabler in these application segments. Microchip automotive solutions such as our microcontrollers, in-vehicle communications and human-machine interface have been a popular choice among automotive suppliers. If we look closely at an EV vehicle, an MCU is required in almost every module or functionality such as electrical control as mentioned earlier, human-machine interfaces for simple things like steering wheel switch buttons, light buttons, seat position buttons, connectivity where every end node of a cable within the car requires some sort of processing module using an MCU. Motor control is only one of the many other applications within a car which require an MCU to fulfil its functionality. The potential for new MCU applications within a car is undergoing tremendous growth as well as the number of motors per car.

From an EV OEM perspective, it begins with the target of achieving more mileage per single charge or how fast the battery gets charged to optimize the driver experience. From these two simple objectives, there are a lot of electronics especially MCU functionality behind the scenes. A microchip is investing in automotive electronic solutions with the objective of maximizing power efficiencies and shortening the development timescale. As an example, in anticipation of the complexity brought by high voltage, high-speed charging and high-efficiency requirements in an electric car, Microchip has dedicated power microcontroller electronics pairing with high voltage capable SiC MOSFET Transistor-Diodes technology which will help suppliers achieve a high-efficiency rating while reducing the development timeframe.

With the current semiconductor industry shortage affecting car OEM production output, it is true that they are paying much more attention to the semiconductors used in their products. The automotive industry covers a wide aspect where cooperation between the OEM, Tier 1, Tier 2 and semiconductor suppliers are vital to ensure a positive end consumer automotive experience. As a leading MCU supplier in the world, Microchip views technical feedback from our customers as vital during the development of new product roadmaps.

In automotive motor control, we are seeing a shift from lower-efficiency 2-phase BDC motors to higher efficiency 3-phase BLDC or even PMSM motors in many traditional body applications. This shift enables the use of control algorithms that reduce the audible noise of the motor which improves customer aesthetics. Note that the vast majority of motor control applications found on combustion engine cars apply equally to EVs because most motors are used in non-engine functions, that is for body and interior functions.

In addition to the need for traction motor control, EVs have created several new motor control opportunities. Belt or engine driven accessories are replaced with electrical motors and several new pump applications are required for battery and inverter cooling. We are also seeing a new trend to consolidate the control of multiple motors and valves for systems such as cooling and thermal management into a single motor controller, for example, to use a dsPIC33CH dual-core DSC. This consolidation reduces the component cost and reduces space requirements by eliminating several PCBs.

Authored Article by:

Automotive Products Group, Microchip Technology Inc.