Kennametal announced its new Mill 4-12KT, the next generation of tangential shoulder mills, producing high-quality floor surface finishes for nearly all steel and cast iron applications.

“The Mill 4-12KT uses15% lower cutting forces, an important consideration with today’s lighter duty, 40-taper machine tools,” said Tim Marshall, Senior Global Product Manager. “That allows customers to feed faster without putting additional stress on the spindle. And in long overhang situations or where the part fixturing is less than optimal, lower forces equate to less chatter, reduced edge chipping, and smoother surface finishes.”

Mill 4-12KT has tangentially mounted inserts with four cutting edges per insert for reduced tooling costs. Seven corner radii from 0.016″ (0.4 mm) to 0.122″ (3.1 mm) are available, along with coolant-through, medium and coarse pitch cutter bodies 2″ (50mm) to 8″ (200mm) in diameter. With an axial depth of cut range from 0.019″ to 0.472″ (0.5 to 12mm), Mill 4-12KT covers most shoulder milling applications.

Multiple factors contribute to significant performance increases, even in aggressive cutting conditions:

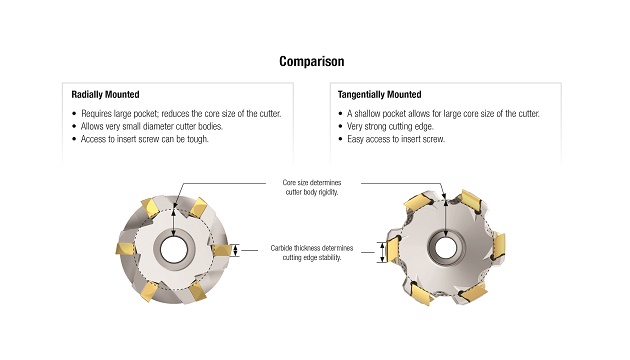

The tangential, “on-edge” insert design also allows the insert to take advantage of the strength of the carbide thickness more so than radially mounted inserts found on traditional milling cutters.

A shallow pocket design, allows the core size of the cutter body to be very robust. The axial and radial seating surface designs provide exceptional stability.

The Mill 4-12KT is the perfect complement to Kennametal’s existing shoulder milling portfolio. This includes the Mill 4-11 and Mill 4-15, cutters known for their ability to generate shoulders with high-quality wall surface finishes.

For more information, visit: www.kennametal.com