Many smart, connected systems, e.g. for Internet-of-Things applications, experience problems with electronics design and production. With its innovative approach, Screvle in Rotselaar, Belgium, executes these steps more rapidly, reliably and affordably. At the core is a modular electronics platform that the company develops since more than five years. The platform enables customers to spread their investments over multiple phases in order to market their solutions faster and optimise the design more efficiently for increasing production volumes. The series of thousands of devices in the market prove the robustness of the custom electronics solutions. Screvle executes the phased process in partnership with customers and minimises the technical and business risks towards a reliable and affordable series product. Screvle grows rapidly and serves diverse verticals by developing electronics for e.g. smart traffic signs, track & trace solutions, terminals for care centers, and even intelligent mousetraps.

Complex tasks kill potential

Building custom electronics is often underestimated. Starting your own developments and calling in various specialists soon becomes expensive and time consuming. In addition, connected systems today are more complex which makes doing everything in-house increasingly difficult. Evolving from a crafted demonstrator to a saleable series product is a lengthy and risky process. Generally, after the market introduction, more defects than expected appear and problems arise with product upgrades. These obstacles hurt the potential of smart, connected solutions which is a pity for the many proven business cases out there.

Working with our unique electronics platform

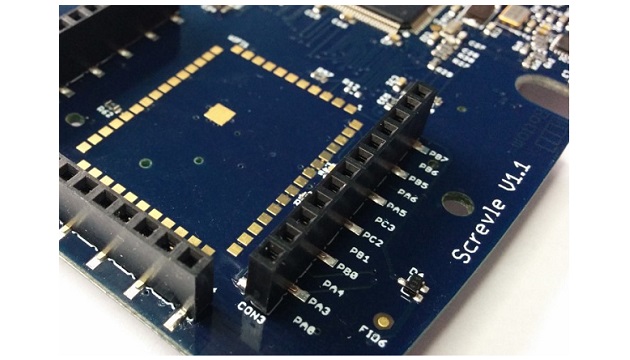

The activities of Screvle originate from freelance work of Founder and CEO Ronald Vanschoren. “Besides project work, we started developing our own electronics platform. A logical step for us because we noticed that customer specifications in different projects are largely similar on a functional level. The platform enables us to develop in a more targeted way and realize proven designs faster. Over the past years we have continued to invest significantly in the platform, both in hardware and software modules. Today, the platform serves as the basis for our services of designing and producing smart, connected devices.”

Clever combination of Telecom and IT

A smart, connected system contains both telecom and IT elements. In a way this is contradictory because telecom and IT are different worlds. In IT, software plays a central role and evolutions like cloud technology facilitate extreme flexibility. In telecom, it concerns physical systems that need to be produced. This presents challenges in terms of delivery times, supply chain, upgrades and economy-of-scale. “These challenges often make system introductions in the market a very expensive and complex process,” Vanschoren indicates. “The Screvle platform allows us to go through a phased process with the customer. We reduce the initial investments by executing the appropriate tasks on the right moments, making the process more accessible as well.”

Screvle continuously invests in the platform by extending it further and integrate technical innovations. “An example is our support of NB-IoT,” says Vanschoren. “NB-IoT is a new, low-power communication technology that operates through the cellular netwerk. Evaluating new technologies and adding these to the platform is an important competitive advantage of Screvle. Also existing customers benefit from platform upgrades free-of-charge.”

The phased approach of Screvle

Before diving into development activities, Screvle starts with discussing requirements and evaluating feasibility. These steps help translate customer ideas into specifications and minimize risks on technical and business levels. Each subsequent phase consist of ‘Engineering/Scaling’, ‘Manufacturing’, and ‘Lifetime Support’. “The Screvle platform allows us to optimize the design in every phase in order to realize increasing production volumes,” Vanschoren explains. “We unburden our customers by offering the entire process from idea to series product, including support throughout the entire product lifecycle. With its efficient approach, Screvle makes custom electronics more accessible, robust, and affordable.”

Specifications and feasibility study:

Screvle starts with an extensive discussion about the plans of the customer to realize a new, connected solution. This entails crystallizing the idea and verifying the feasibility of the business case. Ronald Vanschoren: “We bring on the table significant technical expertise and business experience, which are useful in jointly converging toward a clear and viable list of specifications. This avoids unnecessary risks and enables Screvle to go through the process phases following a streamlined manner, within short periods and without financial surprises. The ‘Specifications and Feasibility study’ can contain a demonstrator which put into practice specific principles of the functionality.”

Proof of concept:

During the Proof of Concept phase, the goal is to end up with one or more engineering samples. “In this process, our specialists realize sharp technical and business requirements using the existing hardware and software modules of the Screvle platform,” Vanschoren clarifies. “After serious consideration and calculation, Screvle proposes the next project phases with detailed cost estimates and leadtimes. When the engineering samples are approved, we prepare the phased rollout toward a reliable series product. De Proof-of-Concept delivers a first version which can be used to gather real-life user feedback. Taking this feedback to heart allows us to properly validate the design.”

Phased roll out:

Today, phased approaches are often applied in software development. The unique solution of Screvle also makes this possible for custom-electronics. Through its platform-based approach, Screvle has built a track record, with orders varying from tens to thousands of devices per year.

Engineering

During this stage, Screvle takes on the design work. For most customers, the design consists for 80% or more out of existing Screvle platform modules and a smaller portion of custom work. Initially, Screvle starts with engineering the necessary elements and gradually adding extra functionality driven by market demands. Essentially, the engineering phase, which includes design certification, prepares the product for production.

Manufacturing

After testing the prototypes, Screvle takes on hardware production and final assembly. Knowing the world of electronics production inside out is a necessity to execute this process rapidly, reliably and affordably. “There are plenty of practical pitfalls that companies are struggling with when producing their designs,” says Vanschoren. “Screvle reduces the risk and the hassle by delivering completely assembled and tested devices. These are ready for use and allow customers to focus on running and growing their businesses.”

Lifetime support

The days a project stops with the delivery of the product have long gone. End customers expect that the product evolves permanently and is supported technically throughout the entire product lifecycle. Screvle operates as a partner and single point of contact, and supports the customer with any further integration needs. When encountering a problem, Screvle specialists are there to identify the problem and come up with a suitable, workable solution.

The lifetime support of Screvle offers customers plenty of advantages that save time, money and effort. The customer can opt to work with a device management system in order to execute many tasks remotely. This allows their products to be monitored centrally through the cloud. They can digitally intervene e.g. by performing updates and resolving problems, often without end users noticing.

Courtesy: www.screvle.com