The automobile industry in India is one of the most important drivers of economic growth, and it plays a vital role with high involvement in global value chains. With strong political support, the automobile sector has grown tremendously, which has helped it carve a unique path among various sectors of India. According to a McKinsey report, India is expected to emerge as the world’s third-largest passenger-vehicle market by 2021.

The automobile industry continues to improve engine efficiency and fuel economy to increase productivity and reduce the adverse effects on the environment due to emissions from the vehicles. There is a larger need to develop a sustainable technology that can comply with all the demands of consumers and standardise the processes. While downsizing, down speeding, direct fuel injection and boosting helps, New Energy Vehicles provide larger opportunities for environmental conservation while fueling economic growth.

Electric vehicles attract extensive interest due to their efficiency in energy consumption, reduction in toxic gases while still giving a cool experience to the users. According to a recent report from Fortune Business Insights, the global EV battery market volume is estimated to reach 40.6 million units with a CAGR of 21.1 per cent by 2026 from 8.6 million units in 2018.

As the world swiftly moves towards Electric Vehicles, it is important to consider the implications and barriers that exist across the ecosystem. Battery management system is the heart of the battery as it plays key role to meet with the functional needs and performance of the battery.

As the EV market is growing, there is an increasing need for an effective battery management system (BMS) to monitor, manage and maintain high-performance batteries and power millions of electric vehicles.It plays a key role in determining and managing the battery and its cells while monitoring and ensuring the safety of the battery and the vehicle. These factors drive the success of the vehicle and its OEM. .

Hence key factors in today’s EVs associated with the battery are the demand for longer range vehicles, decreased charge times, cost and improved functional safety. These exact battery management system requirements necessitate the adherence to the highest of standards with the narrowest of tolerances. Lithium-Ion batteries esp. require considerable care if they are expected to operate reliably over a long period. The battery electronics must be able to communicate information from each cell in a battery stack to a central BMS controller for processing. A typical 400V car would have as many as 120 series cells and many more arranged in parallel. This can complicate the wiring harness design and assembly within a battery pack during construction and subsequently during the service of the pack.

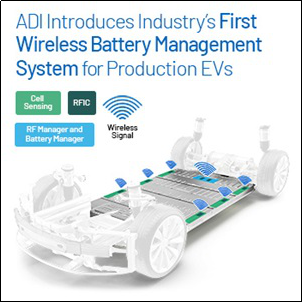

Wireless battery management system (WBMS) is a new disruptive technology that solves this problem efficiently. Built to disrupt the traditional upon existing components of the wired BMS, WBMS eliminates the need for the wire harness that connects the battery cells with the BMS controller for better engineering (mechanical) design and reduced development costs right through the chain of production to support and even monitor the cells for second life. The WBMS makes the design highly modular and scalable so that it can be reused across multiple car designs. In addition the cells can be matched right during the assembly thus maximizing the performance of the pack giving better user experience.

In addition, as power flows into or out of the battery pack, the cells must be accurately balanced to ensure they deliver the highest performance per charge. It ensures top functional battery capacity for the vehicle’s entire lifespan. All the data that is collected from the formation through the use of the cells helps determine a residual value for the battery pack. As each battery module is wireless, it enables a more efficient second use (or a second life), such as in storage, recycling or other applications, reducing the overall cost to the manufacturer and vehicle owner while minimizing the environmental impact.

A battery management system for an electric and hybrid electric vehicle is vital to protect and manage high-voltage batteries. With the rising demand for EVs in the automotive industry, WBMS technology will play a prominent role in the coming days. It will be an integral part of the automotive industry in the time to come. It is the future of the EV industry.