With the ever-increasing worldwide mass production of plastic, the inefficiency of current plastic recycling strategies has raised several environmental, societal, and economic concerns. Magnetic density separation (MDS) is an efficient state-of-the-art recycling technique that uses magnetized fluids to separate different types of plastic particles. Researcher Sina Tajfirooz has developed and validated a model to predict the collective motion of particles in MDS systems. Simulation results shed new light on the separation process in MDS systems and provide data that can help optimize the performance of future MDS systems. Tajfirooz defended his thesis on February 22nd at the department of Mechanical Engineering.

Plastic pollution is a global problem. The production, accumulation, and incineration of plastics directly contribute to climate change, ocean pollution, and infiltration in our food supply.

If the current plastic production and recycling trend continues, by 2050 roughly 12 billion metric tons of plastic waste will have accumulated as waste on our planet. One way to change this trend is through the development of more efficient plastic recycling and separation technologies.

The major challenge in the plastic recycling industry is the efficient separation of plastic waste by type and color, which would also help minimize the chances of high-grade recyclable plastics being mistakenly categorized as lower-grade plastics that cannot be recycled.

Separating plastics with magnetic fluids

Magnetic density separation (MDS) is a separation technique considered by many to be a game-changer in the plastic recycling industry, as it can continuously separate different plastic types from a flow of waste materials.

Like traditional sink-float methods where a mixture of plastics is separated into floating (light) and sinking (heavy) materials. MDS uses Archimedes principle for fluids (buoyancy force on an object is the same as the weight of the fluid displaced by the object) to separate different particles in a mixture.

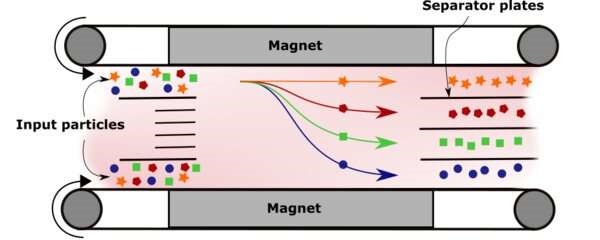

In MDS, a fluid is magnetized by magnets located at the top and bottom of a flow channel (see image). The magnets change the hydrostatic pressure in the fluid and create a gradient of “apparent mass density” in the fluid. In other words, the apparent density of the fluid is different at different heights in the fluid. When the plastic particle mixture is introduced, the particles then move to regions where their mass density equals the apparent density of the fluid.

“MDS is more efficient than traditional separation techniques for a number of reasons,” says Tajfirooz. “It is faster, can continuously separate flows of plastic materials, it can separate multiple plastic types at the same time, and it’s cheaper.”

Taking a simulation approach

Optimizing MDS processes requires a fundamental understanding of the motion of the millimeter-sized particles in flows of magnetic fluids. In his Ph.D. research, Tajfirooz developed an efficient computational model to study particle-laden flows commonly processed in MDS systems.

In the model, particles of varying shapes (from spheres to disk-like particles) and sizes collide with each other and experience a hydrodynamic force from the surrounding liquid. Tajfirooz validated the model by comparing simulation output with the experimental data of Ph.D. candidate Rik Dellaert and several MSc students.

“This work provides valuable insight on the motion of particles in the magnetic fields generated by MDS systems,” says Tajfirooz. “The simulations show that MDS performance efficiency depends on particle size, shape, and the pre-separation processes used to treat the plastic mixture before entering the MDS system.” In addition, Tajfirooz studied the effect of flow turbulence on the separation performance.

Recommendations

From the simulation results, Tajfirooz has recommendations for particle separation in MDS systems. “Larger particles separate more quickly, so it would be best to pre-process the mixtures so that they only consist of larger particles. In addition, spherical particles separate faster than disk-shaped particles, so it would be beneficial if the particles could be pre-processed to be roughly spherical. The resulting decrease in surface area would also help decrease the frequency of particle collisions, which are also shown to increase separation time.”