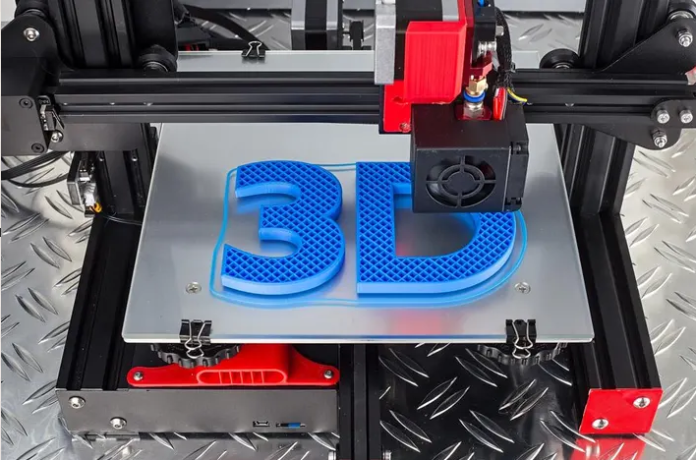

3D printing, or additive manufacturing, is a process of creating three-dimensional objects by building them layer by layer using digital models as blueprints. Unlike traditional manufacturing, which often involves cutting or molding, 3D printing adds material incrementally, enabling precise and complex designs.

History of 3D Printing

- 1980s: 3D printing was invented by Charles Hull in 1983 when he developed Stereolithography (SLA), the first 3D printing technology.

- 1990s: The emergence of other techniques like Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM).

- 2000s: Commercial adoption began, with significant use in prototyping and specialized industries like aerospace and healthcare.

- 2010s: affordable desktop 3D printers became available, catering to hobbyists and small businesses.

- 2020s: Widespread adoption across multiple industries, with advancements in speed, materials, and precision.

Types of 3D Printing

- Fused Deposition Modeling (FDM):

Thermoplastic filaments are melted and applied in layers to build the object. - Stereolithography (SLA):

Utilizes ultraviolet (UV) light to solidify liquid resin layer by layer into a hardened structure. - Selective Laser Sintering (SLS):

Fuses powdered material (plastics or metals) using a laser. - Digital Light Processing (DLP):

Comparable to SLA, but relies on a digital projector to speed up the curing process. - Multi-Jet Fusion (MJF):

Applies a fusing agent to powdered material and heats it to create layers. - Electron Beam Melting (EBM):

Uses an electron beam to fuse metal powder in a vacuum environment.

How 3D Printing Works

- Designing:

A 3D model is created using CAD software or obtained via 3D scanning. - Slicing:

The software divides the model into horizontal layers and creates the corresponding instructions for the printer. - Printing:

The printer constructs the object by adding material one layer at a time. - Post-Processing:

Steps like cleaning, sanding, or painting may follow for a polished final product.

Materials for 3D Printing

- Plastics: ABS, PLA, PETG, nylon.

- Metals: Steel, aluminium, titanium, gold.

- Resins: Standard, flexible, tough, castable.

- Composites: Carbon fiber, fiberglass.

- Ceramics: Clay-based or silica.

- Biomaterials: Used in healthcare for bioprinting tissues.

- Concrete: For construction applications.

3D Printing Technologies

- Layer-by-Layer Deposition: Material is deposited layer by layer as per the design.

- Curing by Light: UV light cures resin or photosensitive materials.

- Powder Fusion: Lasers or beams fuse powdered material into solid structures.

3D Printing Processes

- Material Extrusion: Material is forced through a nozzle in the material extrusion process, as seen in FDM.

- Vat Polymerization: Liquid resin is solidified using UV light (e.g., SLA, DLP).

- Powder Bed Fusion: Powder is melted or fused (e.g., SLS, EBM).

- Material Jetting: Small droplets of material are deposited layer by layer and then solidified.

- Binder Jetting: A liquid binding agent solidifies powdered material.

- Direct Energy Deposition (DED): Material is melted using focused energy during deposition.

How Long Does 3D Printing Take?

- Small objects: A few minutes to several hours (e.g., a phone case might take 1–3 hours).

- Large objects: Can take several days depending on complexity and printer speed.

- Factors affecting time:

- Object size and complexity.

- Layer thickness.

- Printer type and material used.

Advantages of 3D Printing

- Customization: Tailored designs for unique applications.

- Complexity: Ability to create intricate geometries.

- Efficiency: Reduces material waste.

- Cost-Effective Prototyping: Ideal for iterative design processes.

- On-Demand Production: Eliminates the need for inventory storage.

- Eco-Friendly: Reduces waste compared to traditional manufacturing.

Disadvantages of 3D Printing

- Material Limitations: Limited options compared to traditional methods.

- Strength: Parts may not match the durability of traditionally manufactured ones.

- Speed: Slow for mass production.

- Size Restrictions: Printers have build volume limits.

- Post-Processing Needs: Some objects require additional steps for finishing.

- Cost of High-End Equipment: Advanced printers and materials can be expensive.

Industries Using 3D Printing

- Aerospace: Lightweight components for aircraft.

- Automotive: Prototyping and custom parts.

- Healthcare: Prosthetics, implants, and bioprinting tissues.

- Education: Teaching design and engineering concepts.

- Construction: Printing building components or entire structures.

- Consumer Goods: Custom jewellery, footwear, and electronics.

- Manufacturing: Rapid prototyping and specialized tools.

- Food Industry: Printing edible items like chocolates and pizza.

Conclusion

3D printing is revolutionizing industries by enabling innovative solutions that were once thought impossible. Its ability to produce highly customized and complex designs efficiently makes it a cornerstone of modern manufacturing and an essential technology for the future.