Real-time control is the ability of a closed-loop system to gather data, process that data, and update the system within a defined time window. As a continuation of the article, “What is ‘Real-Time Control’ and Why Do You Need It?,” I’ll take a closer look at the first functional block of real-time control systems – sensing (gathering) data – and offer three tips on how to optimize data capture for real-time control systems by paying attention to certain sensor parameters.

You may be monitoring the position and speed of a motor, regulating the output power of an electric vehicle (EV) charging station, or even measuring the closing distance between a vehicle and a car stopped ahead of it. Regardless of the application, important variables for the safety and performance of a closed-loop system include sensor speed, accuracy and reliability.

Tip No. 1: Choose a sensor that gathers and communicates data within your defined time window.

Sensor response, conversion, and communication speeds are extremely important for real-time control systems in which the environment changes rapidly. The faster a system can gather and process data, the quicker it can update its outputs to maintain stability and efficiency.

Let’s look at the example of an EV’s battery pack, where over 40 sensors measure battery cell temperatures. Data from these sensors help maintain the safe operation of these cells and optimizes charging efficiency. The challenge designers often face is that the point-to-point cables holding traditional negative temperature coefficient thermistors add weight and cost to the EV.

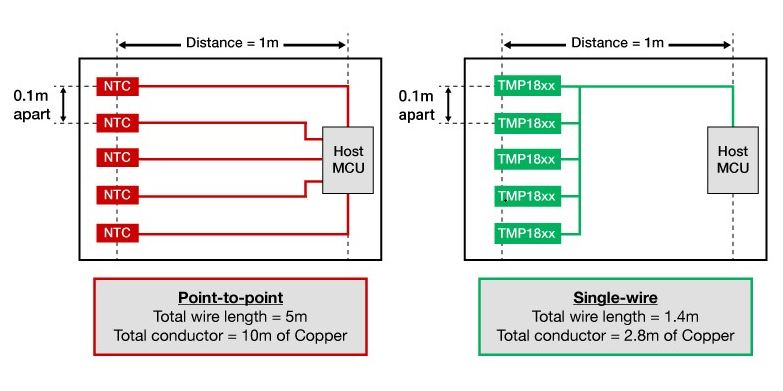

To solve this challenge, as shown in Figure 1, you can adopt the single-wire protocol found in TI’s TMP1826 temperature sensor to reduce the number of cables needed and thus the overall weight, improving vehicle efficiency.

Figure 1: Reducing EV battery temperature sensor cabling

When there are multiple sensors on one bus, however, it’s important to make sure that the communication speed is fast enough for the controller to query a new temperature reading from every single temperature sensor, all within a defined time window. Thankfully, devices such as the TMP1826 support both standard speeds for legacy applications and an overdrive mode with a 90-kbps data rate for low-latency communication, enabling the real-time control system to update each battery module’s cell temperatures properly.

Tip No. 2: Choose an accurate sensor and follow best practices to minimize external errors.

Real-time control systems require precise feedback, and the easiest way to achieve this is by using an accurate sensor. Consider a motor-controlled system such as six-axis robotic arms or collaborative robots, as shown in Figure 2. These robots require precise motor position sensing and control to ensure exactness in assembly processes and safety in cases where there is human interaction.

If you know the motor’s position with greater accuracy, you may be able to reduce mechanical tolerances. In other words, the more accurate your position sensor is, the more margin your design has. A precision Hall-effect position sensor such as the TMAG5170 enables you to accurately monitor a motor’s position while quickly responding to any angular changes so that the real-time control processing unit can reposition the motor accordingly.

Figure 2: Multiaxis collaborative robots

In order to achieve accurate measurements, you must also follow best design practices and consider all possible error sources such as mechanical imperfections of the system or errors related to the signal chain. For real-time control systems requiring precise angular feedback in magnetically sensed applications, follow the guidelines found in the application note, “Achieving Highest System Angle Sensing Accuracy.”

Tip No. 3: Choose a reliable sensor based on your product’s mission profile.

A sensor’s speed and accuracy are two keys for successful real-time control, but you also have to consider the system’s life span and environmental operating conditions to ensure that your sensors operate properly over time. For example, the satellite shown in Figure 3 not only needs to withstand intense physical vibrations and large amounts of radiation in space, but also extreme temperature variations.

Figure 3: Space is a particularly harsh environment for electronic components

One example of real-time control in space is found within power generation and distribution systems on satellites, which use current-sense amplifiers (CSAs) to monitor their main power rail input current in order to detect single-event transients. Upon the detection of an overcurrent event, the processor can react in real time to shut down electronic subsystems and prevent damage.

TI leverages technology advancements such as space-enhanced plastics and radiation-hardened packaging in CSA products such as the INA901-SP and INA240-SEP to maintain highly accurate measurements and enable real-time control in space. To learn more, check out the technical article, “How Current-Sense Amplifiers Monitor Satellite Health.”

Conclusion

Sensing often refers to the measurement of external variables such as voltage, current, motor speed, position, humidity and temperature. A sensor’s response time, communication speeds, accuracy and reliability are important parameters to send data changes in real time to the control system.